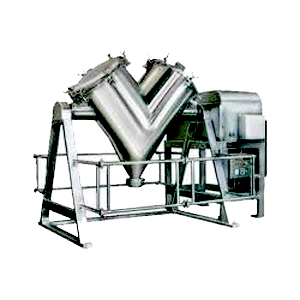

V Blender

The V-Blender (also known as a twin shell blender) is one of the most commonly used tumbling blenders. The blending performance of this type of blender has shadowed many of the members in the blender family. They offer both short blending times and efficient blending. The V-Blender is made of two hollow cylindrical shells joined at an angle of 70° to 90°. The blender container is mounted on trunnions to allow it to tumble. As the V-blender tumbles, the material continuously splits and recombines, with the mixing occurring as the material free-falls randomly inside the vessel. The repetitive converging and diverging motion of material combined with increased frictional contact between the material and the vessel’s long, straight sides result in gentle yet homogenous blending. The blender mounted on fabricated ‘A’ shape stand with plummer block bearing. One side of the stand provided with drive assembly. For higher capacity material loading, drum with trolley can be provided.

Capacity: 1 kg to 1500 liter capacity. Capacities as per requirements.

Application

- Particle size reduction and attrition are

minimized due to the absence of any moving blades. Hence it can be used

for fragile materials - The shape of blender body results in a near

complete discharge of product material, clearly an added advantage over

horizontal blenders. - The absence of shaft projection eliminates product contamination.

Optional:

- MOC S.S. 316,316L,304.

- Vaccum conveying system for powder loading and unloading.

- Full unit in GMP or standard model.